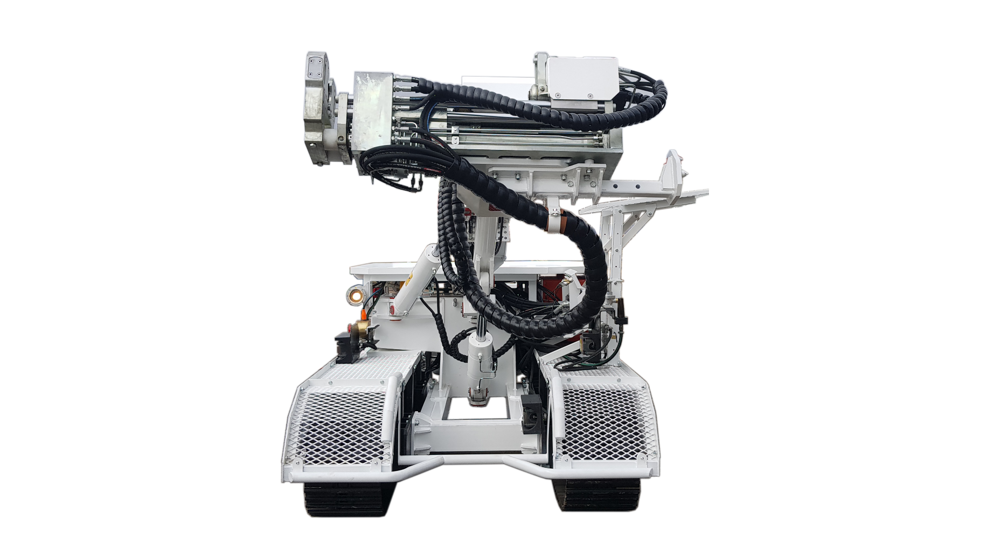

CMR7 MANTIS HYBRID

Supplier Information

Name:

Conax Machine Solutions Pty Ltd

Contact:

Byronde la Mare

Phone:

0118172290

Email:

sales@conaxms.co.za

Website:

http://www.conaxms.co.za

Address:

58 Watt Road, New Era, Springs, Gauteng, 1559

Datasheets

CMR7 MANTIS HYBRID flameproof, electro-hydraulic or diesel/hydraulic, crawler rig roofbolter / face drill This is essentially two machines for the price of one. The MANTIS HYBRID is designed for a quick change out from the CFF two-stage telescopic, rotary drilling, roof bolting feed frame to the CFP fixed, face drilling feedframe. This process takes approximately 1.5 hours. Applications: Secondary Support Bolting Roof and Rib Bolting Face Drilling (coal and hard rock) - S3 Rotary Drill or quick change to Doofor DF530S Rock Drill Roof Coring Water Hole Drilling

| Equipment Type |

|

|---|---|

| OEM |

Conax Machine Solutions |

| TRL |

TRL9 |

| Mining Type |

Roofbolter / Face Drill |

| Mine Development |

Mine Development, Access Development, Logistics |

| Mining Activity |

Drilling, Supporting, Roof Coring, Water Hole Drilling |

| Mining Method |

None |

| Mineral |

Any |

| Energy source |

|

| Logistics & materials handling |

|

| ITComms |

|

| reefType |

|

| Transport Height: | 1350 mm |

|---|---|

| Width: | 1995 mm |

| Length: | 4720 | 7300 mm |

| Min Ground Clearance: | 255 mm |

| Weight: | 6150 to 7000 kg |

| Electric Motor: | 30 kW |

| Voltage: | 525/1000 VAC |

| Diesel Engine (option): | 45 kW |

| Max Hydraulic Oil Pressure: | 210 bar |

| Max Hydraulic Oil Flow: | 135 lpm |

| Feedframe Height - collapsed (Roof Bolting): | 1400 and 2060 mm |

| Max Supported Drilling Height: | 2300 and 3800 mm |

| Max Drill Travel: | 1510 and 2800 mm |

| Max Feed Thrust: | 1450 kg.f |

| Max Torque: | 375 Nm |

| Max Rotation Speed: | 520 rpm |

| Chuck Size: | 22 (hex) mm |

| Max Water Flushing Pressure: | 8 bar |

| Feedframe Length (Face Drilling): | 3132 mm |

| Max Drill Travel (Face Drilling): | 2300 mm |

| Max Height Horizontal Drilling: | 3250 mm |

| Min Height Horizontal Drilling: | 150 mm |

| Max Feed Thrust (Face Drilling): | 450 kg.f |

| Hydraulic Drifter Power: | 10 kW |

| Max Torque: | 175 Nm |

| Max Rotation Speed: | 250 rpm |

| Shank Size: | R32 mm |

| Max Water Flushing Pressure: | 8 bar |

| Excellent stability and manoeuvrability (track driven, skid steer) | |

| Narrow gauge for easy access to tight areas | |

| Walk behind tramming control with deadman selector valve | |

| 2-stage telescopic rotary drilling feedframe | |

| Fixed feedframe for face drilling - percussion (hard rock drilling) and rotary (coal face drilling with S3 Drill Head) | |

| Highly efficient 2 person bolting operation | Single person face drilling | |

| Robust, easy to operate and maintain |

.png)