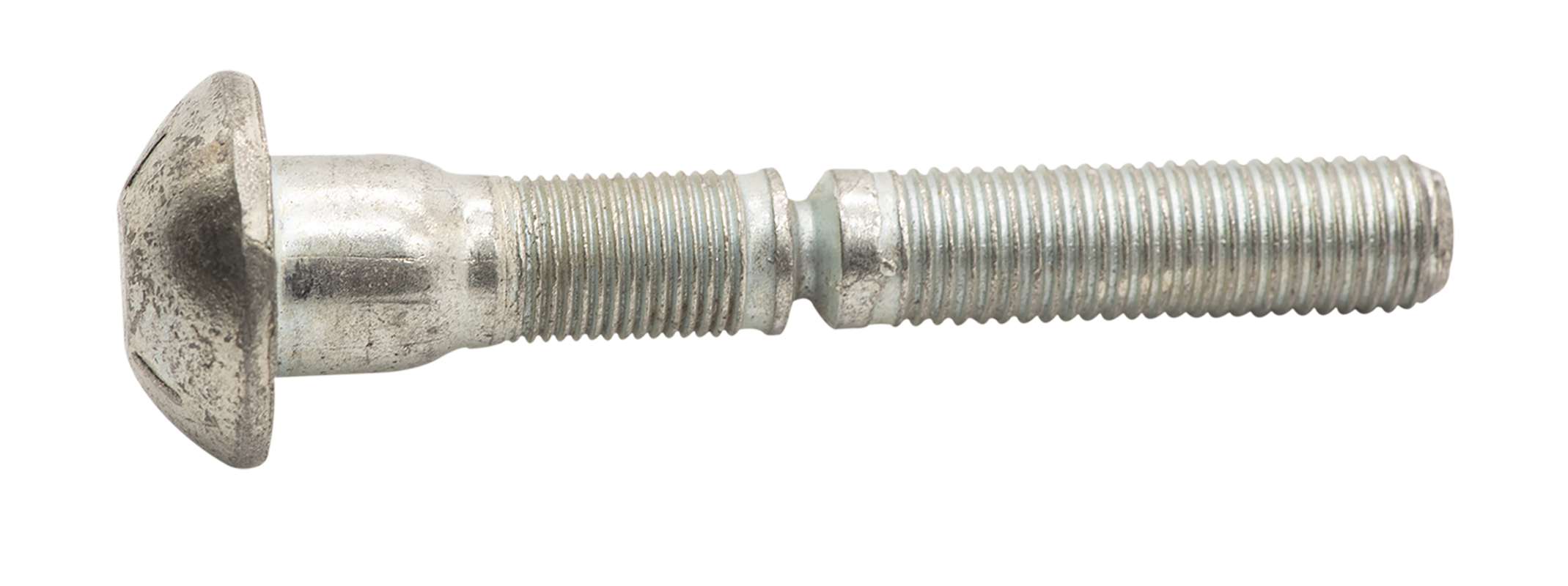

Step Down (SD) Oversized Swagebolts

Supplier Information

Name:

Swagefast (Pty) Ltd.

Contact:

Wilna Pienaar

Phone:

27116684600

Email:

sales@swagefast.com

Website:

https://www.swagefast.com

Address:

09 Monument Dienspad Street, Olivanna, Krugersdorp, Gauteng, 1739

Vibration and shock can quickly impair joint integrity and affect overall product performance. The Swagefast Fastening System offers a highly vibration resistant joint owing to its unique design in which the collar is swaged into the annular locking grooves of the Swagebolt – ensuring a permanent lock. Proven for use in multiple industries, the Swagefast™ Fastening System is ideal for heavy duty, high vibration applications, combining shear strength with quick and easy installation – resulting in a virtually foolproof solution that gives the assurance of long-term joint reliability. The majority of the fasteners in the system have been designed to meet or exceed SAE Grade 5 or ASTM A325 and ISO (8.8) strength requirements, ensuring high clamp force, tensile and shear strength depending on the application. Step Down (SD) Oversized Swagebolts: * Two-part fastener that comprises a Swagebolt Pin (with a defined breakneck) and a Collar; * Used for reworked holes and applications where access is limited; * The Swagebolt hank diameter is larger to accommodate the oversized holes; however, the grooved section is stepped down one or two diameter sizes to accommodate the Tool.

| Equipment Type |

Fasteners |

|---|---|

| OEM |

Swagefast |

| TRL |

TRL8 |

| Mining Type |

Surface mining,Mineral Processing and Beneficiation,Underground mining |

| Mine Development |

Prospecting,Stoping,Shaft Sinking,Access Development,Development |

| Mining Activity |

|

| Mining Method |

Mechanised,Conventional,Hybrid,Autonomous |

| Mineral |

Gold & Platinum,Coal,Diamonds,Base Metals,Other |

| Energy source |

|

| Logistics & materials handling |

Pipe services,Tramming & Rock Handling,Transport |

| ITComms |

|

| reefType |

|

| Fasteners never need to be tightened/torqued due to the annular locking groove design | |

| High vibration stress tests prove that the fasteners consistently maintain 98% of their pre-load | |

| Visual inspections can confirm correct fastener installation | |

| Wide grip ranges decrease fastener part numbers and inventory levels | |

| Uniform clamp force is consistent | |

| Long-term joint reliability | |

| Longer fatigue life | |

| Vibration resistant | |

| Virtually no rework | |

| Reduced downtime | |

| Tamper resistant/proof | |

| Increased productivity | |

| Lower installation costs | |

| Consistent installation results | |

| Improved product quality and reliability |